Ravi is working as a Quality Assurance Manager with over 15 years of experience in the pharmaceutical industry. One morning, he had just settled into his daily routine. Suddenly, his phone buzzed with urgency. It was a call from the front desk.

“The FDA is here for an audit—they’re waiting in the lobby,” said the front-desk executive.

His heart dropped.

Just last week, the plant had flagged a critical deviation, and the validation reports were still pending final review. As he rushed down the corridor, several questions went through his mind: What if they find the gap? What if production is halted? What if this costs people their jobs?

His phone wouldn’t stop ringing—calls from the plant head, senior managers, and endless notifications. A message popped up from the plant head, “We cannot afford even a single critical observation.”

Ravi approached the auditors with trembling hands and a forced smile. But his anxiety was visible all over his face. Without saying a word, his body language betrayed the plant’s non-compliant state.

But Ravi’s story isn’t unique. Many pharmaceutical professionals face similar high-pressure situations.

So, what behaviors or practices lead to such critical moments? Let’s explore.

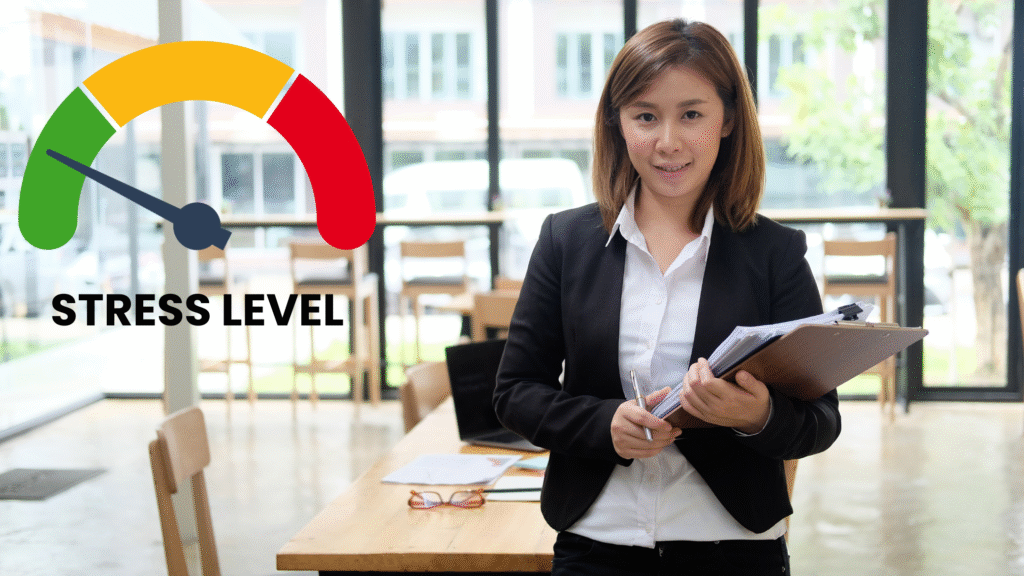

Audits in the Pharmaceutical industry are always a critical part of ensuring compliance. However, they can be highly stressful for professionals involved, from quality assurance teams to plant managers and operators. The fear of non-compliance findings can lead to significant stress. If not managed properly, this stress can affect performance, decision-making, and overall well-being.

Why Are Pharmaceutical Audits So Stressful?

Pharmaceutical audits can be intense due to the high stakes involved. Unexpected findings during an audit can trigger serious consequences, ranging from regulatory warnings and product recalls to temporary or permanent plant shutdowns. These outcomes not only affect the company’s reputation but can also impact the careers of individual employees.

Each audit is unique. Even if the same auditor has visited before, their focus areas can change. This unpredictability arises from the fact that auditors receive continuous training on the latest regulatory standards and evolving expectations, making it difficult to anticipate their line of questioning.

Moreover, ensuring that every document—whether it’s a batch record, SOP, deviation report, or CAPA—is accurate, up-to-date, and readily available is a difficult task. Preparing for audits often demands long working hours, contributing to mental and physical fatigue, which further amplifies the stress associated with the process.

Pre-Audit Preparation

1. Develop a Robust Compliance Culture

A strong quality culture helps minimize last-minute panic during audits by encouraging preparedness and accountability across the organization. This can be achieved through regular internal audits to identify and address gaps early, continuous training of employees on Good Manufacturing Practices (GMP) and compliance standards, and promoting open communication where staff feel comfortable reporting issues without fear of blame.

2. Assign Clear Roles & Responsibilities

To ensure a smooth and organized audit process, it is essential to clearly define roles and responsibilities in advance. Assign a qualified individual, such as the QA/QC head or plant manager, to lead the audit. Designate subject matter experts from each department to escort the auditors and provide relevant explanations. Appoint a dedicated document controller to manage and fulfill all documentation requests efficiently. Additionally, establish a rapid response team to address any findings or issues immediately. Having this clarity not only reduces confusion and delays during the audit but also helps prevent overlapping duties and ensures a professional, coordinated approach.

3. Conduct a Pre-Audit Checklist

A week before the audit, it’s important to conduct a thorough review to ensure readiness on all fronts. Begin with documentation—carefully check batch records, deviations, CAPAs, and change controls for accuracy and completeness. Next, assess the facility and equipment, making sure everything is clean, properly calibrated, and that all preventive maintenance is up to date. Finally, focus on personnel readiness by briefing staff on potential questions auditors may ask, so they can respond confidently and accurately during the inspection.

4. Get Enough Rest Before the Audit

Fatigue can significantly impair judgment, which is why both you and your team must be well-rested and mentally prepared before an audit. Make sure everyone gets a good night’s sleep beforehand to stay sharp and focused. Avoid excessive caffeine, as it can heighten anxiety and reduce clarity under pressure. Instead, opt for a balanced meal that provides sustained energy throughout the day, helping maintain concentration and composure during the audit process.

5. Maintain an Audit-Ready Facility

Instead of rushing at the last minute, pharmaceutical companies should adopt an “Always Audit-Ready” mindset. This approach involves maintaining up-to-date and well-organized documentation through electronic systems such as a Quality Management System (QMS). It also requires ensuring that equipment logs, calibration records, and validation documents are current and readily accessible. Regular mock audits can help simulate real audit scenarios, allowing teams to identify and address potential gaps in advance. Encouraging a cultural shift toward real-time, digital documentation and providing continuous training on Good Documentation Practices (GDP) and accurate record-keeping are also essential steps in staying consistently prepared for audits.

During the Audit

1. Adopt a Positive Mindset

Adopting a positive mindset is key to handling audits effectively. Instead of viewing the audit as an interrogation, consider it a valuable learning opportunity. Keep in mind that auditors are not there to punish, but to help identify areas for improvement and strengthen the existing systems.

2. Practice Active Listening

During an audit, it’s important to be an active listener. Allow the auditor to complete their question before responding, as interrupting may lead to miscommunication or appear unprofessional. If you’re uncertain about an answer, it’s perfectly acceptable to say, “Let me confirm that with the right person,” rather than guessing or providing incorrect information. Always maintain a calm and professional behavior. Do not react defensively, even if the question feels critical.

3. Manage Time Effectively

Effective time management is crucial during audits. Prioritize tasks based on urgency, especially when auditors request specific information or documents. If they require additional time to review a particular area, be flexible and adjust your schedule accordingly to ensure a smooth and cooperative audit process.

4. Use Stress-Reduction Techniques

To manage stress effectively, it’s helpful to incorporate simple stress-reduction techniques into your routine. Deep breathing exercises—such as inhaling for four seconds, holding the breath for another four, and exhaling slowly for six seconds—can quickly calm your nervous system. Taking short breaks to stretch can also ease muscle tension and improve circulation, helping you feel more relaxed and focused. Additionally, staying well-hydrated is crucial, as dehydration can intensify feelings of stress and fatigue.

5. Handle Difficult Questions Gracefully

When faced with a difficult question from an auditor, it’s important to handle it with composure and professionalism. Start by acknowledging the question with a positive remark such as, “That’s a great question,” which shows openness and confidence. If the question is unclear, seek clarification by asking, “Are you referring to the X or Y process?” This ensures that your response is accurate and relevant. When answering, focus on providing structured, fact-based information rather than assumptions. This approach not only demonstrates your knowledge but also builds trust and credibility with the auditor.

Post-Audit Management

1. Debrief with Your Team

After the audit concludes, it’s important to debrief with your team to help manage any lingering stress and ensure continuous improvement. Gather everyone to openly discuss what went well during the inspection and identify areas that need improvement. This not only helps in learning from the experience but also prepares the team better for future audits. Additionally, taking the time to acknowledge and appreciate your team’s efforts can reinforce a culture of support and collaboration.

2. Address Findings Proactively

Addressing audit findings proactively is crucial for maintaining compliance and avoiding repeated issues. Start by categorizing the observations based on their severity—whether they are critical, major, or minor. Once categorized, develop and implement appropriate Corrective and Preventive Actions (CAPAs) without delay to ensure that root causes are addressed effectively and future occurrences are prevented.

3. Reflect & Improve

Update any procedures that need refinement, incorporating lessons learned into your quality system. If knowledge gaps or skill deficiencies contributed to observations, schedule targeted follow-up training to strengthen competencies.

Conclusion

Pharma audits are inherently stressful, but with proper preparation, a calm mindset, and effective stress management techniques, you can eliminate them successfully. By implementing an always audit-ready culture, maintaining clear communication, and prioritizing well-being, you’ll not only survive audits but succeed in them.

Remember: Stress is manageable, and every audit makes your processes stronger. Stay prepared, stay confident, and keep excelling in pharmaceutical compliance!

Three months later, as Ravi reviewed another flawless audit report with zero observations, he finally exhaled—not with relief, but with quiet pride. The systems he’d built now ran so smoothly that even FDA inspections felt like routine conversations, not crises.